![[tb-dynamic provider='__current_post' post='current' source='post-title' force-string='first' ]](https://unisystem.com/wp-content/uploads/2023/08/matryca-tn-en-1-1024x576.webp)

History and development of TN matrix technology

The TN matrix originated in the 1970s. It made its debut in the 1970s in the first calculators and digital watches. The name TN stands for twisted nematic and comes from the twisted liquid crystal molecules that are a key component of this LCD technology. Initially, TN matrices had very limited capabilities, allowing only the display of simple numbers and characters.

Table of Contents

The breakthrough came in the 1990s. along with the development of TN color displays. It became possible to obtain a full-color image by adding RGB filters to each pixel. TN matrices were ideal for use in modern liquid crystal monitors, where the speed of displaying dynamic content mattered. Thanks to their simplicity, low production price and low power consumption, TN screens quickly dominated the monitor and display market.

However, in the 21st century, new LCD matrix technologies such as IPS and VA began to appear, gradually displacing TN matrices. With better color reproduction and wider viewing angles, they performed better in applications requiring high image quality, especially on modern TVs.

Nevertheless, due to advantages such as low price and low power consumption, TN matrices are still widely used. They are readily used in cheaper monitors and televisions, as well as in mobile electronics. They can be found in industrial, medical and military equipment, as well as in older models of laptops. Thanks to continued technical development, TN matrices continue to be an important part of the industrial and consumer electronics market.

TN matrix – construction and principle of operation

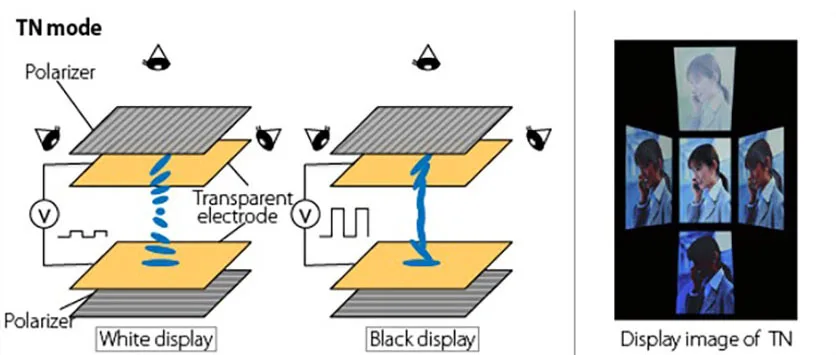

The classic TN LED matrix consists of two glass substrates coated with a transparent, conductive layer of ITO (indium tin oxide). Between the substrates is a liquid crystal layer. From the outside, the matrix is covered with polarizers arranged perpendicular to each other.

In the natural state, the molecules of the liquid crystal are twisted by 90 degrees, which causes a rotation of the plane of polarization of light penetrating the TN layer. This allows light rays to pass through both polarizers and the pixel brightens.

On the other hand, when an electric voltage is applied, the TN particles align themselves parallel to the planes of the glass. Then the plane of polarization of light does not rotate and is blocked by the second polarizer. As a result, the pixel darkens.

By adjusting the voltage, you can precisely control the degree of twist of the liquid crystal molecules, and thus the brightness of each pixel. This allows the image to be displayed in grayscale and in full color when RGB filters are added. Precise voltage control for hundreds of thousands of pixels allows TN matrices to display sharp images and video.

Modern TN matrices have a number of improvements to enhance image quality. These include improved LED backlighting, reduced streaking and glare, or increased color depth. However, the basics of operation have remained the same for decades – regulating the twisting of liquid crystal molecules with an electric voltage.

TN matrix types

Over the years of development, several varieties of TN matrices have been developed, with different parameters:

- STN – Super Twisted Nematic – this type of TN matrix has higher contrast, lower voltage

- FSTN – Film Compensated STN – applying a compensating filter to one of the polarizers increases contrast and viewing angles

- DFSTN (or FFSTN) – Double Film ST N – double layer of STN filters, even better contrast and viewing angles

- HTN – High Twisted Nematic – very high twist of molecules and different polarization angle, so operation at low voltages, wide operating temperature range

- VATN (Vertical Alignment Twisted Nematic) – relies on the natural alignment of liquid crystals vertically offering higher contrast, deep blacks, better viewing angles and no grayscale inversion, but resolution is limited to 16 pixels

Each of these technologies has different applications, depending on the technical requirements of the product.

TN matrix advantages and applications

TN matrices have numerous advantages that have given them a dominant position in the market for decades:

- Low production price, due to simple design and lack of additional components

- Low power consumption, possible battery operation

- Fast response time, 2-5 ms, support for dynamic content

- High brightness and contrast, good color reproduction

- Ability to produce large diagonals, even above 40″

These features make the TN matrix suitable for a wide range of applications:

- LCD monitors and screens

- Electronics in industrial, medical, military equipment

- Message boards, billboards, screens in vending machines

- Older laptops, calculators, watches, digital cameras

The main disadvantages of TN are inferior color reproduction and lower contrast, compared to IPS or OLED matrices, as well as narrow viewing angles. Hence, IPS and VA matrices are more commonly used in newer TVs. However, the advantages of TN still determine their popularity in many areas of industrial electronics.

Comparison of TN matrices with IPS and VA technologies

TN vs IPS matrix

Compared to the popular IPS matrices, TN screens are characterized by:

- Narrower viewing angles, which limits the readability of the presented image

- Weaker color reproduction and inferior black reproduction

- Faster response time – e.g., 2-5 ms for TN vs. 5-15 for IPS

- Lower production price due to simpler design

For these reasons, IPS matrices are better where image quality matters – in professional graphics monitors or modern industrial equipment, such as HMIs.

TN vs VA matrix

With respect to VA matrices, TN displays are characterized by:

- Lower contrast and poorer black reproduction

- Slightly narrower viewing angles

- Faster response time – 2-5 ms (TN) vs 15-30 ms (VA)

Thanks to their higher contrast ratio, VA matrices are better suited for video and photo viewing, where image quality matters.

Summary and future of TN matrices

In conclusion, twisted nematic dies have dominated the consumer electronics market for many years due to their simplicity, low production costs and low power consumption. They are an integral part of monitors, TVs, laptops and many other devices. However, in the latest applications requiring high image quality, they are increasingly being displaced by newer technologies such as IPS or VA.

The future of TN matrices is therefore uncertain. On the one hand, their advantages continue to determine their popularity in many fields. On the other hand, technological advances in displays are gradually turning away from TN in favor of more modern solutions. However, even if the basics of TN technology are being pushed out, as a display manufacturer we believe that knowledge of TN technology remains extremely valuable to every electronics and display engineer.